MTL optical measuring machine

Titolo diapositiva

Scrivi qui la tua didascaliaPulsanteTitolo diapositiva

Scrivi qui la tua didascaliaPulsanteTitolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

MTL optical measurement

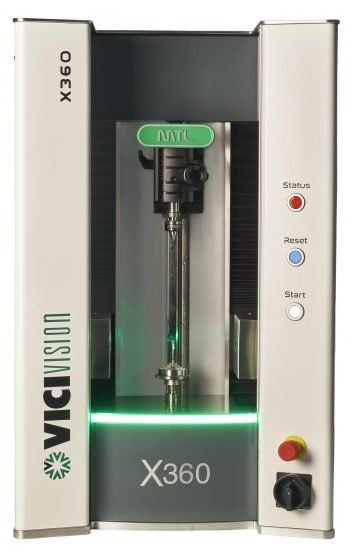

Check Solution's range of equipment also includes the MTL Optical Measurement machine. Ideal for turned and ground pieces, MTL consists of a sturdy single-piece column structure in cast aluminium with appropriate stiffening ribs, perfect for protecting the machine from the oil of the production environment. The vertical carriage that moves the optical system and the tailstock for fixing the upper piece slide on the column. The whole system is solidly fixed to the machine base with direct support on the work surface.

All the machining of the mechanical parts are performed on Cnc-tooling centres in a single set-up to avoid misalignments due to the repositioning of the elements.

Every detail of the MTL optical measuring machine is designed to facilitate its use:

- the vertical arrangement of the piece facilitates the fixing operations, by placing the element directly on the lower tailstock or on the clamping chuck, it reduces the risk of the piece falling during the measurement and guarantees the minimum deformation of the element during rotation measurements;

- the absence of doors allows wide and direct access, even with two hands, to the piece fastening area;

- the loading area with LED lighting provides excellent visibility in all conditions;

- the absence of openings and undercuts prevents small pieces from falling into the machine;

- the presence of the step-master allows instant and automatic feedback of the measurements performed;

- the vertical fixed piece and moving optical unit minimise vibrations, also with large and heavy pieces.

Optical measuring unit

The MTL optical measuring machine works without contact, thus combining precision, speed and rapid setup of the piece change.

MTL uses a system consisting of a linear camera and a telecentric backlight, moved vertically along the entire length of the piece. The two cameras create a high resolution image of the entire piece to measure, then processed by powerful analysis software

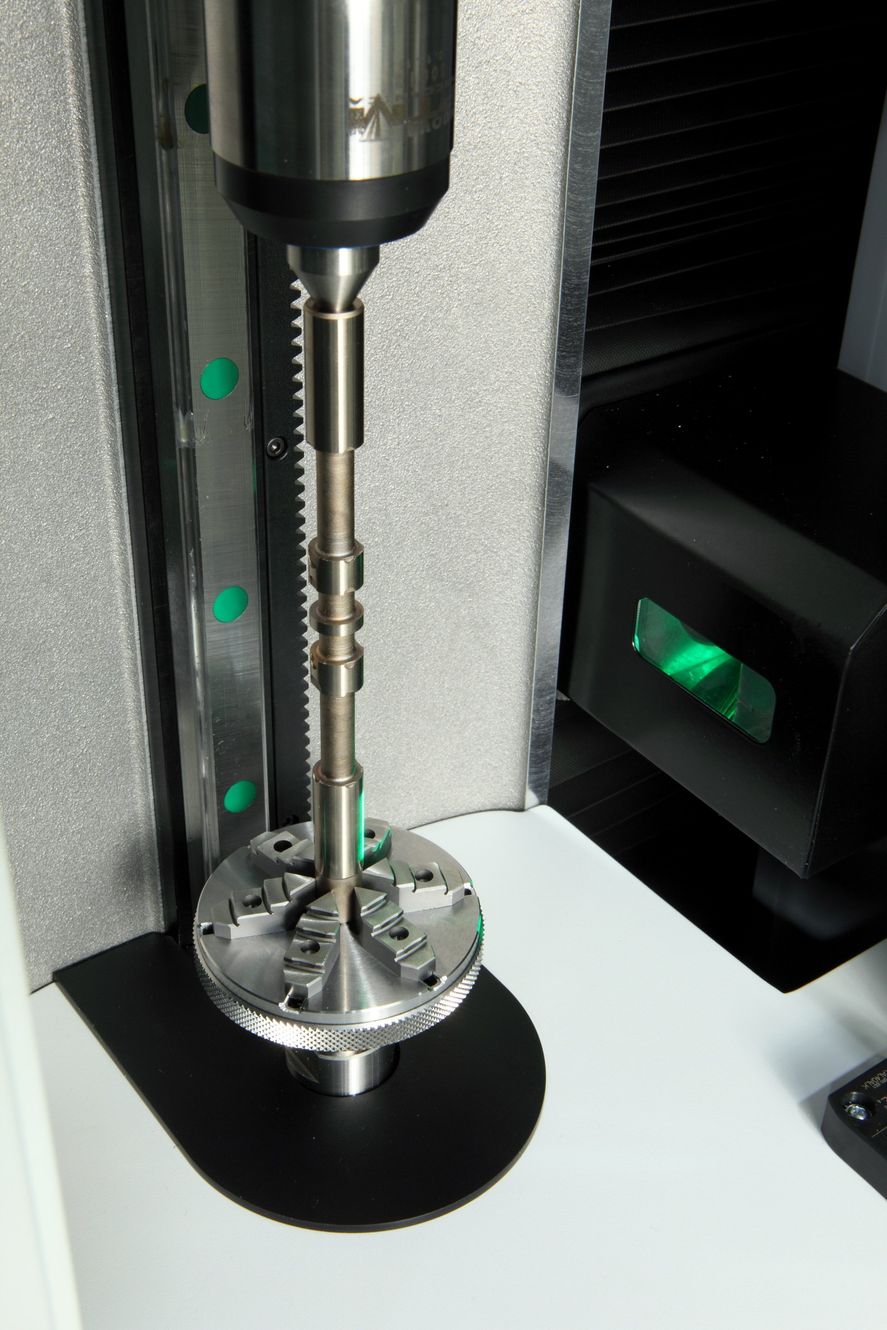

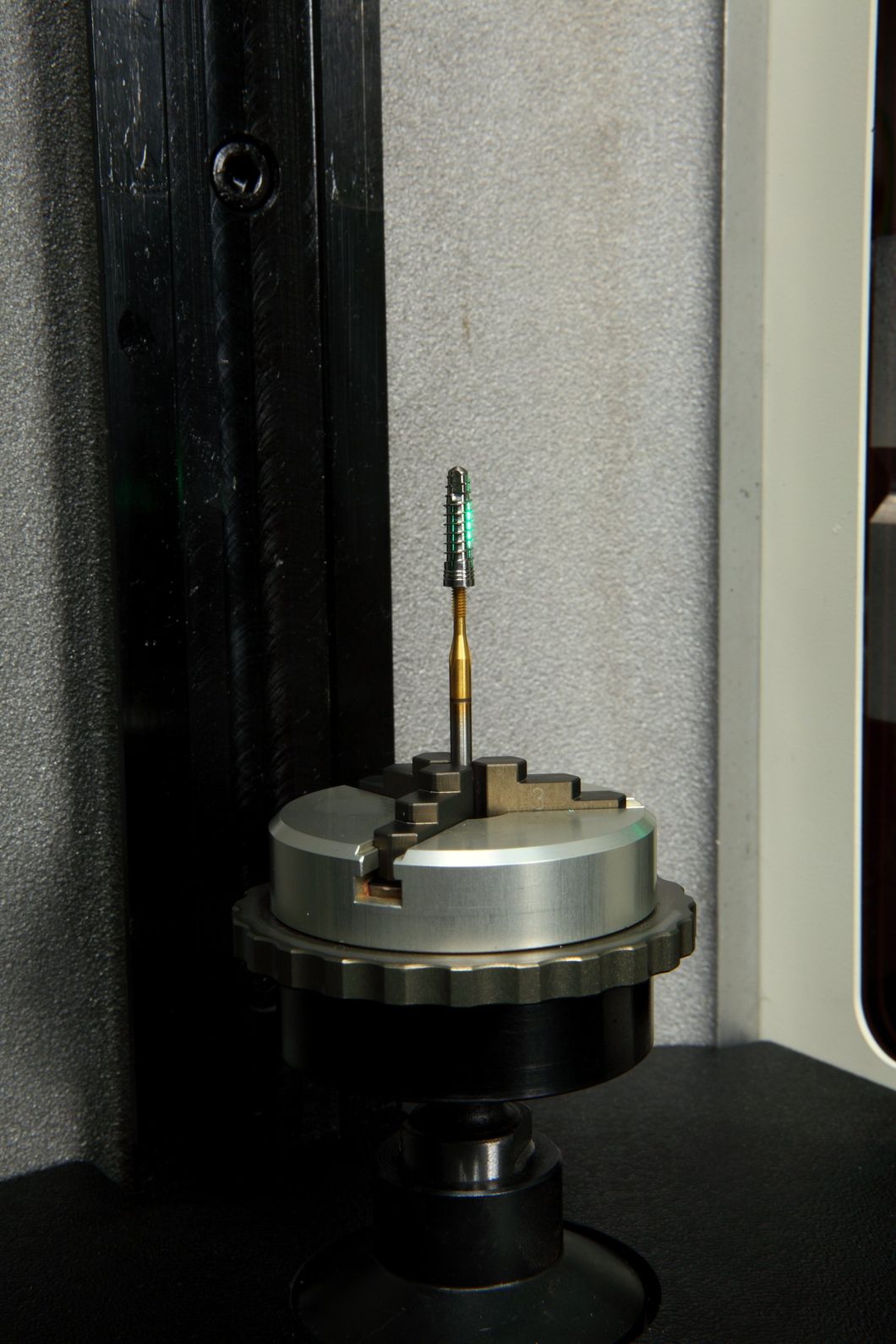

Piece clamping and rotation unit

The MTL optical measuring machine is equipped with an upper tailstock (rotating, driven) and a lower dragging tailstock (fixed) connected to a rotation system, both with Morse taper attachments. This makes it possible to interface the machine with the standard fastening systems used in the workshop and a wide range of interchangeable accessories (cusps, jaw chucks, etc.) makes it possible to fasten any type of piece to be measured.

The upper tailstock, which can be moved for length adjustments, has a weight balancing device that makes positioning easier. The tailstock sliding takes place on a prismatic guideway with recirculating ball slide and lever locking device, to ensure maximum rigidity combined with alignment precision. The adjustment movement obtained by means of racks gives it extreme practicality. For locking and unlocking pieces, a lever with a large vertical stroke allows maximum speed to change the piece.

Titolo diapositiva

Scrivi qui la tua didascaliaPulsanteTitolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

List of standard measures included in the MTL programme

- Scanning measurements (for acquiring images of the piece under analysis and finding its references within it): vertical, rotational, multi-position, piece start, piece end, piece rotation, phasing (e.g. cams, keys), cycle repetition, positioning;

- Reference measurements: line-line intersection, line-plane, line-circumference, circle-circle, plane, known diameter position, axis, distances, minimum/maximum point;

- 2D Measurements (Static): Diameter (Min/Med/max); Distance (vertical/horizontal/free/referred to the piece axis/referred to the machine axis);

Angle; Radius; Chamfer dimensions (angle, length, height); - Comparison measures and mathematical calculations: distance to points, sum (off-set), difference, sin., Cos., Tan. etc;

- Rotating diameter measurements: minimum, medium, maximum, interrupted diameter, turned diameter (coarse finishes);

- Angular position measurements: angular timing of cams, keyways/keys, through holes, shoulder milling, interrupted diameters;

- Shape measurements: circularity, coaxiality, radial run-out, axial run-out, cylindricity (LSC, MIC, MCC, MZC);

- Thread measurements (analysis of the average or of the single ridge); pitch, diameter height (maximum, minimum, average, rollers quota); crest angle; LG/NG share;

- Conical thread measurements: pitch, height, taper, average diameter, ridge angle;

- Geometric measures: straightness, perpendicularity, parallelism, symmetry;

- Measurements on hexagon (or N-sided polygons): key, asymmetry, timing;

- Chamfer size (angle, length, height);

- Linearity, orthogonality, parallelism, symmetry measurements;

- Offline programming on the real image of the piece or DXF file.

| Technical data example M1 | |

|---|---|

| Model | M1 |

| Maximum measurable piece | 300x60 mm |

| Maximum loadable piece | 300x60 mm |

| Maximum loadable piece | 10 kg |

| Measurement accuracy on diameter (average diameters) | (2+D[mm] / 100) µm* |

| Length measurement accuracy | (5+L[mm] / 100) µm* |

| Replicability of measurements on diameter (average diameters) | 0,4 µm* |

| Replicability of measures on length | 3 µm* |

| Vertical scan speed | 100 mm/s |

| Rotational scan speed | 1080 °/s ** |

| Machine weight | 175 kg |

| Power supply | 230V ? 50/60 Hz ? 1,73A |

| Dimensions LxWxH | 595 x 780 x 950 mm |

| Requires electro-welded steel support table or granite top (suggested dimensions) WxDxH | 700 x 800 x 1200 mm |