SURFACE measurements: TAYLOR HOBSON

Another brand that Check Solution represents is Taylor Hobson, a leading company in the field of surface checks and measurements. We can offer their entire range of tools and direct the customers towards the solution that best suits their needs.

In addition, Taylor Hobson's new advanced software ensures sizing according to component diagrams, features a simple and intuitive interface with virtual visualisation and real-time checks, and offers exact reproduction of the component coordinate system (PCS).

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

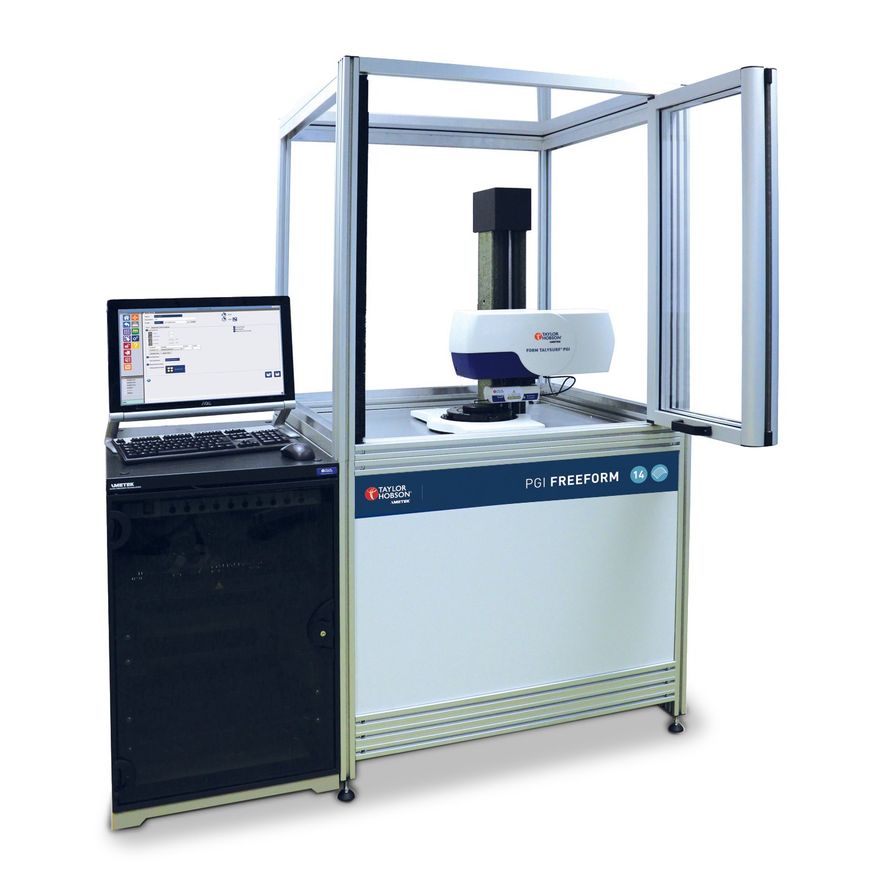

Surface profilometers

They are designed and manufactured to the highest standards to offer surface finish, surface roughness, pitch height, diameter, angle and contour measurement for applications such as precision optics, performance heads and blocks, gears, sheet metal , workshop work and other manufacturing applications.

Thanks to decades of experience, ultra precision machining expertise and FEA optimized design, these tools provide flawless, low-noise mechanical execution of the measuring axes. Working closely with manufacturers operating in various sectors, it was possible to study the tools needed to focus on the key characteristics, proposing a flexible solution for all measurement needs, devising a variety of specific systems and accessories as well as the possibility of making custom-made equipment according to the specific needs of the customer.

Roughness measurements can be easily carried out on multiple components and the results are available in the internal memory or can be transferred to an external USB memory. They

can also

be printed and given

to the customer, or can accompany the component to the next stage of the production process. .

It is also possible to monitor wear and changes in roughness over the life of the product, to detect early signs that indicate the presence of defects or leaks, in terms of efficiency.

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Contactless 3D optical profilometers

To the features described in the previous paragraph regarding optical profilometers, we can add that these tools are used for the measurement of aspherical, diffractive and free-form lens/optical shapes and are designed for non-contact and ultra-precise 3D measurements of shapes of rotational symmetrical surfaces.

This solution offers the greatest number of benefits for surfaces with steep slopes and variable pitch directions and small surfaces, such as smartphone lenses and related moulds.

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsanteTitolo diapositiva

Scrivi qui la tua didascaliaPulsante

Roundness and shape

Taylor Hobson's roundness/cylindricity measuring tools allow customers

to analyse, at sub-micron levels, precision components in fully automatic or semi-automatic CNC operations. Whether in inspection chambers, calibration labs or workshops, Taylor Hobson's broad range of instruments offer the versatility and accuracy customers

demand.

For example, there are large capacity roundness systems, which are specially designed to measure large components, regardless of diameter or weight, while maintaining shape and roundness accuracy.